BEST-IN-CLASS AUTOMATION FOR CANNABIS PRODUCTION

Improving productivity with advanced control solutions

AC Servo: Drives & Motors

MAIN APPLICATIONS:

- PH & Nutrition Irrigation control

- Ampoules Filling

- Packaging Sorting control

- Weight automation

- Bagging automation

Complete Control Solution - with Servo made Simple

Main Features:

Automatic communication setup, Ready-made code: implement Motion in 2 clicks, Motion Control programming: drag & drop function blocks, Control up to 8 Axes, One-parameter tuning, Built–in Diagnostic tools, Wide servo power range, Robust, built-in high-resolution serial encoders and more!

AC Servo: Drives & Motors

Servo made Simple: we do the work for you! Benefit from:

- Ready-Made Motion code with every purchase:

- No Motion programming needed: simply download and tap a panel – even mobile – to:

– Set motion parameters

– Monitor Axis behavior and I/Os

– Execute movements, such as Point-to-Point, Jog, and Homing - Communications: Automatic setup, absolutely seamless

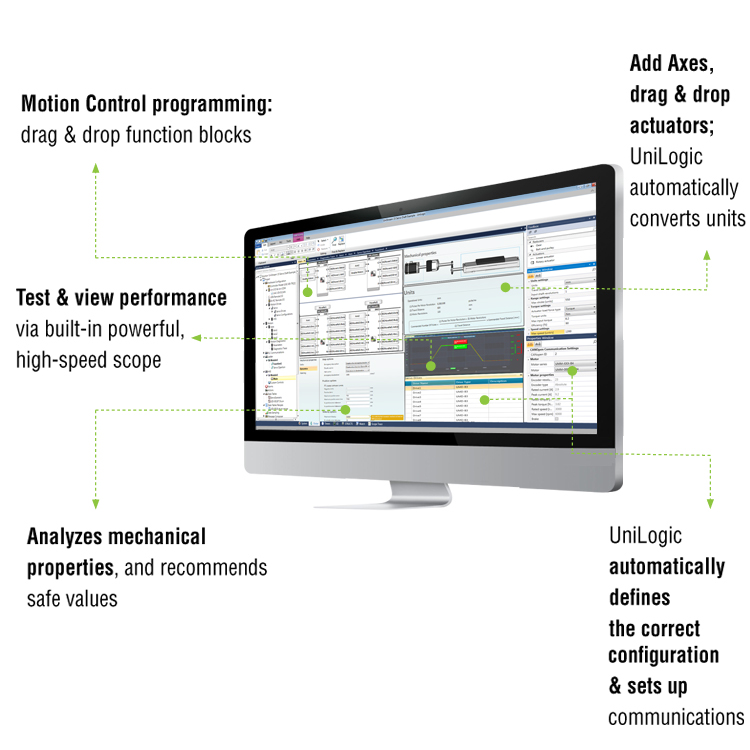

- Minimizes Error: UniLogic software analyzes mechanical properties and recommends safe values for your application

- Diagnostics: View servo run-time performance via UniLogic’s built-in powerful, high-speed scope

- Tune your system: Using only one single parameter

Complete Control Solution - with Servo made Simple

- Hardware

- Software

- Drives: 1 and 3-phase, robotic cables available

- Wide servo power range – 50W to 5,000W (0.06-6.7 HP)

- Motors: to suit any machine size; robust, built-in high-resolution serial encoders (absolute: 23-bit , incremental: 20-bit), IP65

- CANopen built-in (EtherCAT: available soon)

- Servo drives and Motors: simple setup

- Ready-made code: implement Motion in 2 clicks

- Motion Control programming: drag & drop PLCopen-compliant function blocks

- Control up to 8 Axes

- One-parameter tuning

- Built–in Scope & Diagnostic tools

UniLogic® Makes Motion Control Simple

Eliminate the complicated operations associated with Motion Control!

Powerful, award-winning software that enables you to do it all in one project!

- Configure all hardware: PLC, HMI, Servo drives, motors, actuators

- Build PLC, HMI, and Motion applications

- Set up and implement all communications—including Industry 4.0

TABLE DOWNLOAD- SERVO

PRODUCT OFFERING

File Name

Product Offering

Download

MOTOR SPECIFICATION

File Name

Motor Specification

Download

DRIVE DIMENSIONS

File Name

Drive Dimensions

Download

DRIVE SPECIFICATION

File Name

Drive Specification

Download

PRODUCT DESIGNATION

File Name

Product Designation

Download

UMM-B2 & UMM-B3: MOTOR DIMENSIONS

File Name

UMM-B2 & UMM-B3: Motor Dimensions

Download

UMM-B4: MOTOR DIMENSIONS

File Name

UMM-B4: Motor Dimensions

Download

Ubermorgen Innovations Gmbh:

“For me, most important is that I forgot that it is there - and it does its job, a very important job, controlling steam production for our factory.”

Coating Systems:

“We have found Unitronics to be one of those companies which inspire you to push the boundaries, we are reinventing a control system that has been around for many years on different platforms but with Unitronics we actively look to see how we can improve the product using the available technology but without it adding additional cost for our customers.”

Mar Cor Purification:

“The development process went a lot smoother due to the operator interface and PLC as one, and being programmed as one simultaneously…There are no annoying hurdles to jump, no additional communications software, communications hardware, or support costs. There is no burdensome software over protection getting in the way—just layout a design and build away!"

Timbersoft:

“The most cost effective and reliable way to fill the entry level PLC/HMI/SCADA bracket in the market.”

Aqua Interma Engineering:

“Among all automation the devices I work with, Unitronics is my favorite.”

AquaRD:

“With a friendly development environment and unrivaled quality to price ratio, Unitronics PLC’s are the perfect solution – we highly recommend them!”

Imapsa Automation:

"With fast delivery times, and constantly updated software, Unitronics has always listened to our customers many requests, and have implemented them since we decided to start our automation division in 2001. Great support via both the technical support team and the Unitronics forum. And, of course, great price!"

Greenmove Technologies:

“The Unistream offers the right balance between functionality and simplicity and is therefore an ideal fit for our application. With the Unistream we succeed in running our ‘mini-factories’ at the locations of our customers.”